Case Study

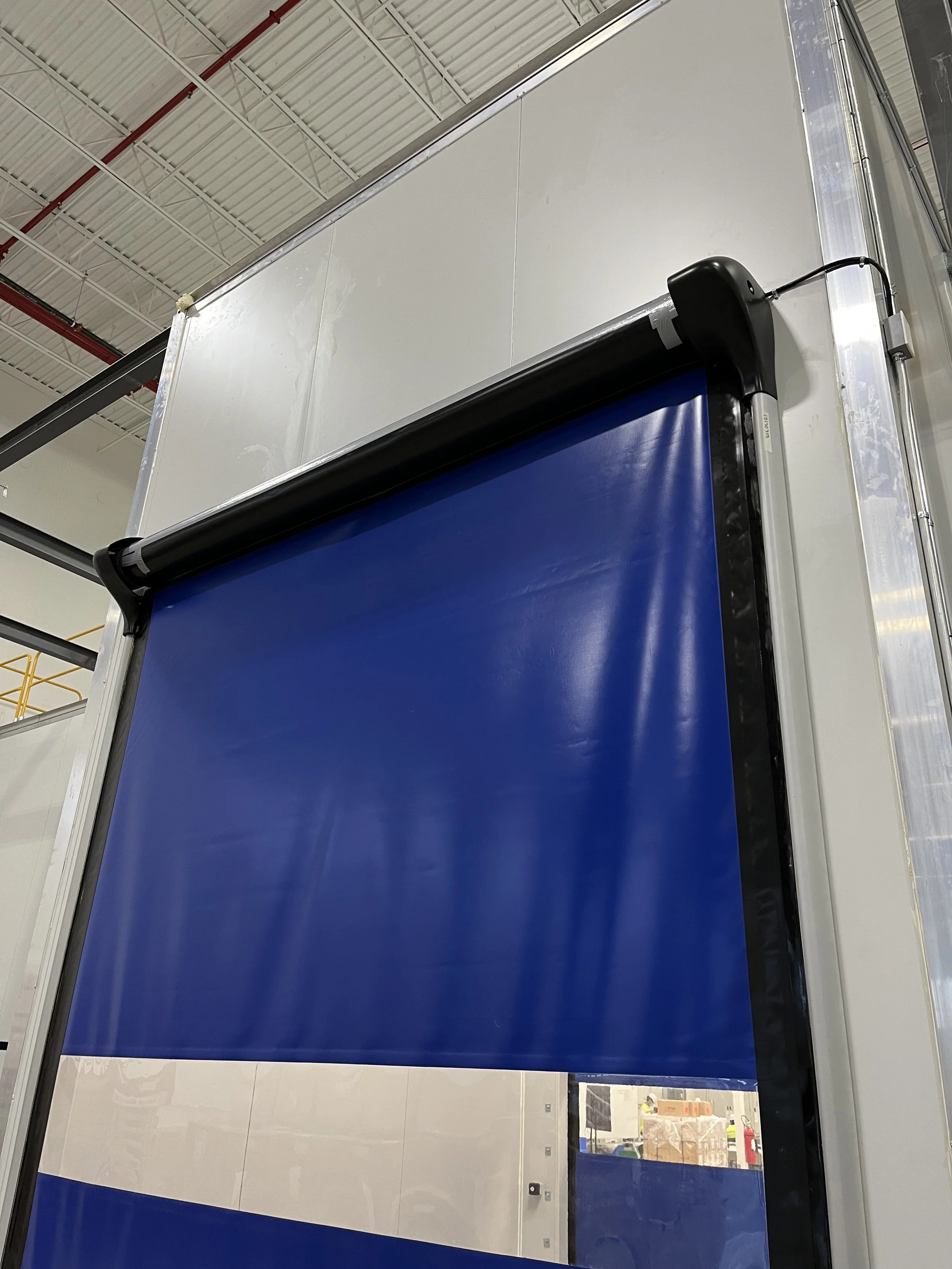

Energy Storage Systems Dry Room

Location: Detroit, MI

Size: 20,000 ft²

Timeline

Rooms Constructed

Jan 2023

Order Confirmed

Oct. 2023

Dec. 2023

Final Handover

Before Construction

During Construction

After Construction

Project Highlights

-

This project required ~186,000 CFM of recirculation air. Airtho’s standard Plenum FFU design, while utilizing Airtho proprietary HEPA Hub, reduced the number of FFU’s from 248 standard FFU’s to 31 HEPA Hubs. 248 standard FFU’s consume 104 kW of power, and 31 HEPA Hubs only consume 60 kW of power. Airtho’s standard design methodologies and proprietary components saved an average of 385,440 kWh per year.

-

Airtho consistently accommodated room changes including layout redesigns, door adds and changes, interior wall shifts, increase in room square footage, etc. all while construction was taking place. Airtho was able to accommodate all these changes while maintaining timeline.

-

Airtho remained flexible during the design, construction, and commissioning phases to ensure the customer received an environment that allowed them to succeed.

Project Photos