Case Study:

Isolator Cleanroom in Rhode Island

Size: 512 ft²

Location: Woonsocket, RI

Timeline: 5 months

Overview

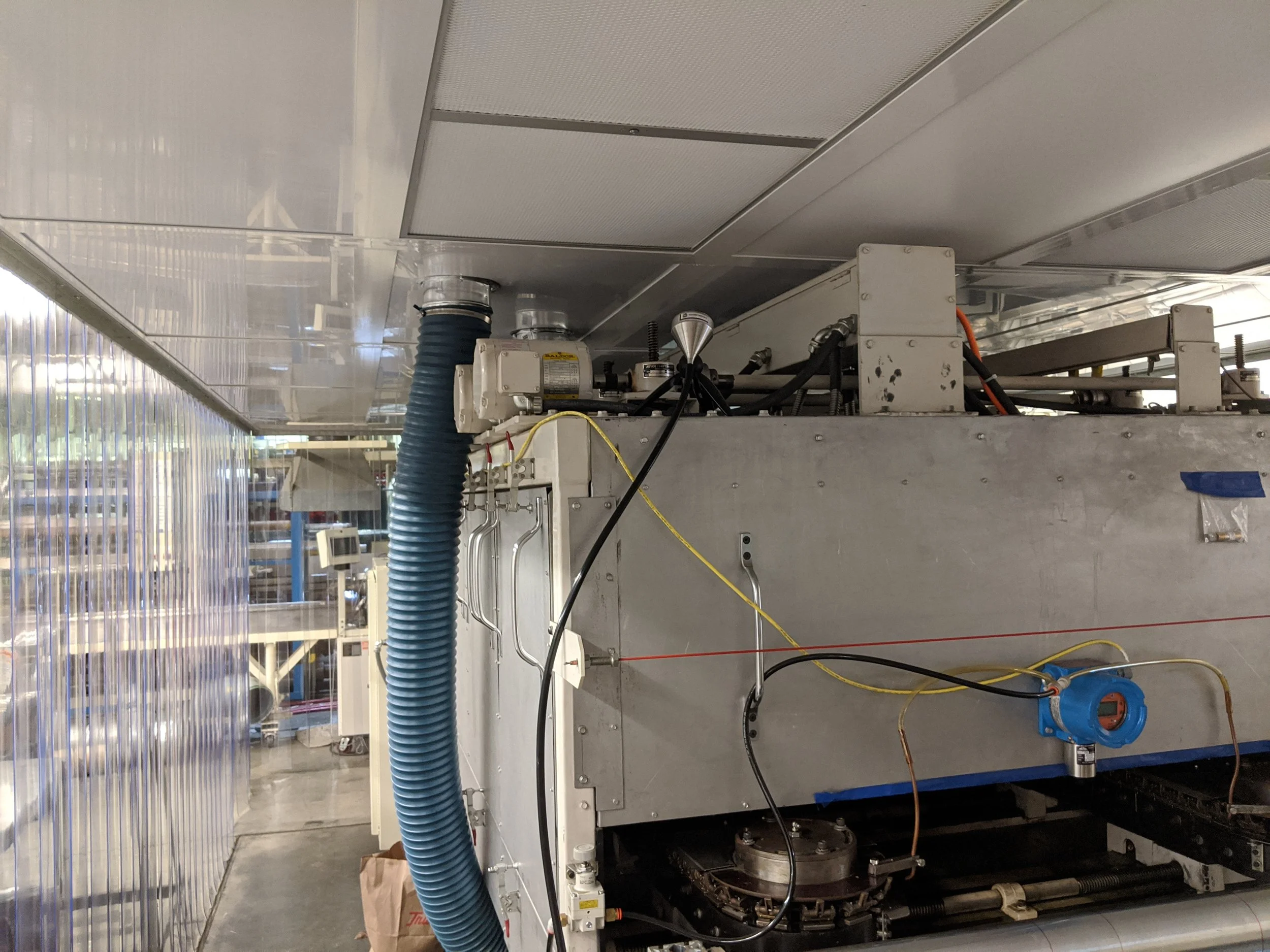

Airtho partnered with a biotechnology manufacturer to design and deliver a compact, high-performance isolator cleanroom that could be integrated into an existing production space. The project required a modular system capable of achieving ISO 6 and ISO 7 cleanliness, efficient recirculation airflow, and precise environmental control—all while fitting around existing equipment and infrastructure.

Challenge

The client needed a fully engineered isolator room within a facility that offered limited overhead space, existing mechanical obstructions, and strict cleanliness requirements. The installation had to support high air-change rates, integrate VRF cooling and makeup air, and maintain proper pressurization—despite the compact footprint and tight coordination zones.

Solution

Airtho engineered a cleanroom system that maximized both performance and constructability:

High-Efficiency Airflow Design: A combination of Airtho Cell Fan Kits and ducted HEPA filtration provided more than 150 ACH in the isolator area and 30+ ACH in the surrounding zones. The system utilized 2×4 HEPA modules strategically positioned within the Intelligrid™ layout to maintain ISO 6/7 conditions.

Integrated Cooling & Makeup Air: A 2-ton VRF indoor and outdoor unit supplied conditioned makeup air while supporting room pressurization. Flexible 10" insulated ductwork was used to route air efficiently within the cleanroom footprint.

Modular Architectural System: The cleanroom enclosure incorporated 4" aluminum-clad wall panels, softwall strip-curtain entries, and a suspended Intelligrid™ ceiling system designed to support HEPA filters, lighting, and blank panels without structural modification to the building.

Long-Term Serviceability: Airtho provided ongoing support, including a field visit to inspect and restore VRF unit performance by re-leveling the indoor unit, correcting condensate drainage, and verifying airflow after adjustments.

Results

Stable ISO 6/7 cleanroom performance with high-efficiency airflow

Seamless integration into an existing production environment

Compact mechanical design supporting high ACH and positive pressurization

Modular ceiling and wall system requiring no major building upgrades

Continued operational reliability supported through responsive field service