Case Study:

Isolator Cleanroom in Rhode Island

Size: 404 ft²

Location: Woonsocket, RI

Timeline: 5 months

Overview

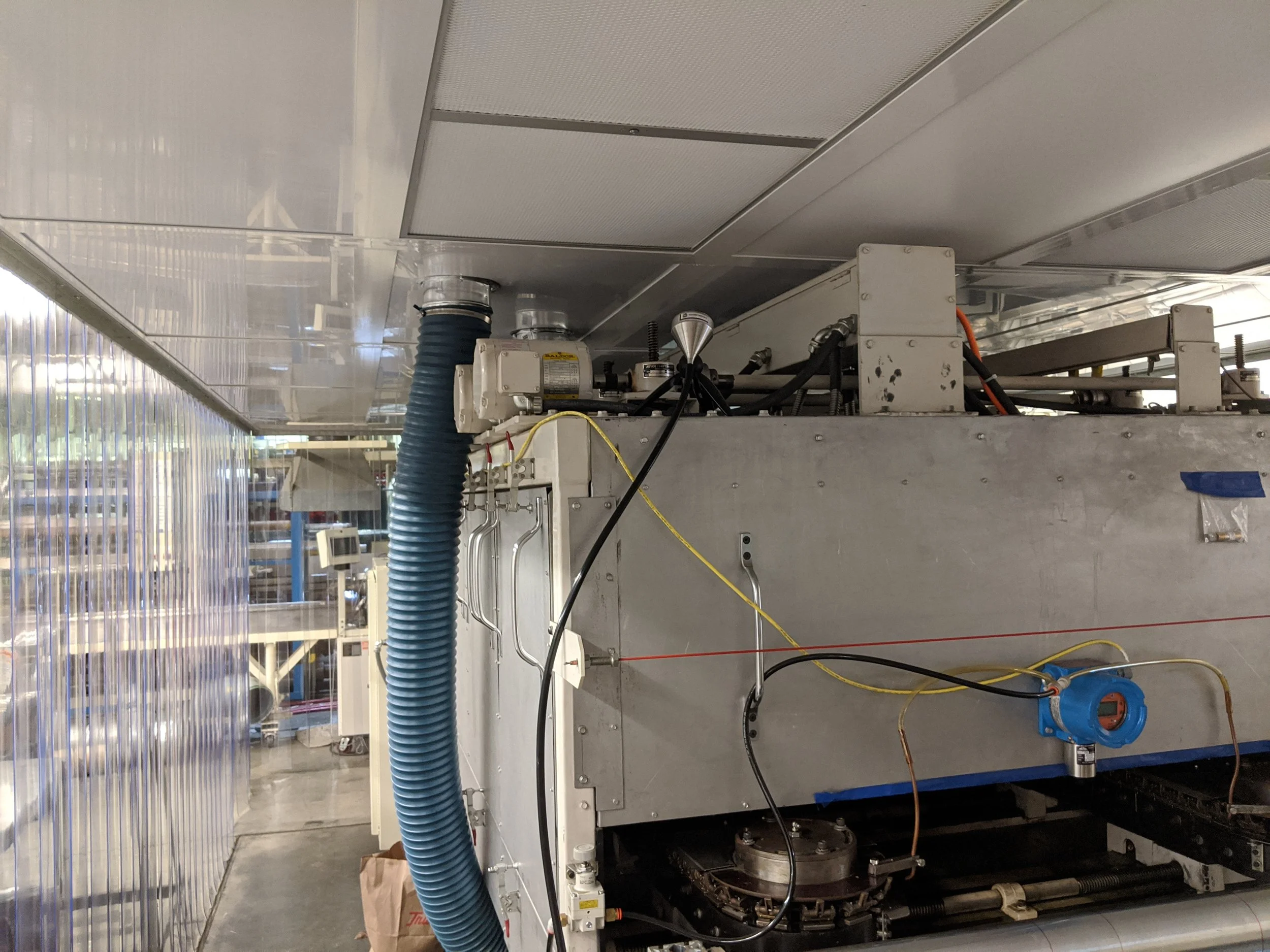

Airtho partnered with a biotechnology manufacturer to design and deliver a compact, high-performance isolator cleanroom that could be integrated into an existing production space. The project required a modular system capable of achieving ISO 7 cleanliness, efficient recirculation airflow, and precise environmental control—all while fitting around existing equipment and infrastructure.

Challenge

The client needed a fully engineered isolator room within a facility that offered limited overhead space, existing mechanical obstructions, and strict cleanliness requirements. The installation had to support high air-change rates, integrate VRF cooling and makeup air, and provide conditioned and HEPA filtered air—despite the compact footprint and tight coordination zones.

Solution

Airtho engineered a cleanroom system that maximized both performance and constructability:

High-Efficiency Airflow Design: An Airtho HEPA Hub Kit supplying 84 ACH with eFRM HEPA modules was strategically positioned for maximum performance in process critical areas, outperforming ISO 7 cleanliness specifications.

Integrated Cooling & Makeup Air: A 2-ton Fujitsu VRF heat pump system supplied conditioned makeup air while supporting room pressurization.

Modular Architectural System: The cleanroom enclosure incorporated Airtho Modular Wall™ Panels, softwall strip-curtain entries, and a suspended Intelligrid™ ceiling system designed to support HEPA filters, lighting, and blank panels without structural modification to the building.

Results

Stable ISO 7 cleanroom performance with high-efficiency airflow

Seamless integration into an existing production environment

Compact mechanical design supporting high ACH

Modular ceiling and wall system requiring no major building upgrades

All proven parts with design, installation management and start-up by Airtho’s project management team